CO2-neutral energy supply in energy-intensive industry - energy4CHP

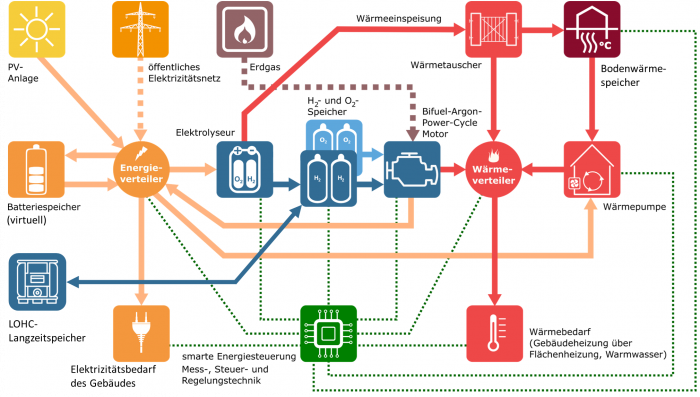

The object of the joint project is to implement an integrated control and regulation system for the CO2-neutral supply of electricity and heat to the test halls of a research company. In terms of building technology requirements, the test halls of the WTZ correspond to those of a processing commercial enterprise. The focus here is on the technical integration of the main components:

– Electrolysis plant

– Bifuel CHP with ArgonPowerCycle technology (APC)

– Photovoltaic system

– Hydrogen storage infrastructure including LOHC storage – Ground heat storage with heat pump

The WTZ subproject comprises the development of a bifuel ArgonPowerCycle CHP, an oxygen storage system and the automation of the overall compound system. In the project, the recirculating engine and gas storage tank will be put into continuous operation under real conditions. The proposed gas engine has two operating states and uses either green hydrogen or alternatively natural gas as fuel gas. The first state corresponds to the zero-emission cycle engine with ArgonPowerCycle technology (APC) by converting hydrogen back into electricity in a highly efficient manner. After the capacity of hydrogen is used up, natural gas can be burned in the same engine in the alternative state. Thus, the storage size of hydrogen is kept within limits.