GENERAL INFORMATION ABOUT THE SIMULATION

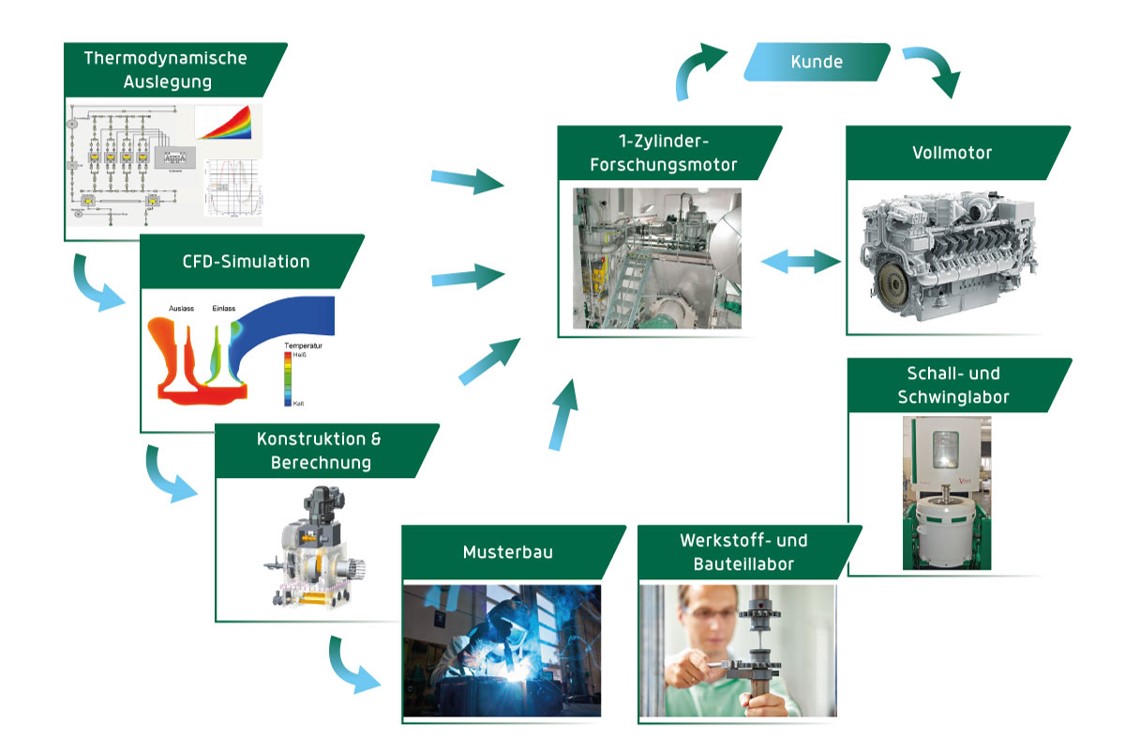

Before production, each new component undergoes a development process in the simulation phase, which determines the framework conditions using various tools such as thermodynamic design and 3D flow simulation. The results of the simulation are incorporated into the structural design and calculation of the components.

FIELD OF TASKS

The WTZ Roßlau provides support for demanding and challenging tasks and carries out calculations and simulations of machine components using analytical and numerical methods.

- Strength calculations

- Structural analyses, linear and non-linear statics

- Eigenvalue calculations

- Frequency response analysis

- Proof of operational stability

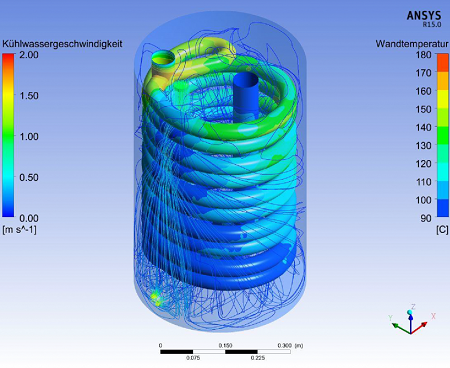

- Thermal analyses

- thermomechanical analyses

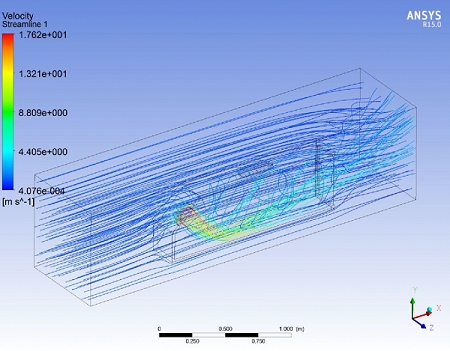

- Flow calculations

- Calculation of mechanical engineering parts

CORE COMPETENCIES

The WTZ Roßlau has been working on topics and projects in the field of combustion engines for decades.

The core competencies here are in the area of large gas, diesel, heavy fuel oil and dual-fuel engines for stationary and mobile applications in the industrial and marine engine sector. In today’s product development process, the aim is to achieve ever faster development cycles while at the same time reducing costs. Components must be designed to be ever more powerful and efficient without compromising the stability and service life of components and systems.

THE DEVELOPMENT PROCESS CHAIN

With the help of 0D/1D simulation, the thermodynamic design and determination of boundary conditions is carried out. These are taken into account as system boundaries in the 3D CFD simulation. The pre-selection of components can already be made on the basis of the preliminary design with the simulation tools. The results of the simulation are incorporated into the structural design and calculation of the components. The production, post-processing and finishing of test components can be carried out in our in-house prototyping department. The components produced are mounted on WTZ single-cylinder research engines.

GOALS

- Combustion Process Development

- Optimization of efficiency and emissions

- Component testing

PRACTICAL EXAMPLES