PROTOTYPE CONSTRUCTION

WTZ Motorentechnik GmbH develops and manufactures high-quality components, assemblies and machine construction devices for engines, devices and testing equipment. One focus is on the implementation of product-related development tasks.

WTZ Motorentechnik GmbH lives by tradition high performance, unrestricted customer orientation and uncompromising adherence to delivery dates. We have experience in mechanical production of samples, prototypes and small series, construction of special machines and accessories. In addition, with our experienced and qualified employees, we have extensive materials, development and production know-how.

OUR STRENGTHS

WE...

- realize samples, prototypes and small series quickly, reliably and cost-effectively

- show you innovative and individual solutions for your needs

- Are experienced, powerful and flexible to meet your requirements

- have a sound and broad knowledge of materials science, coupled with many years of practical experience

OUR SERVICES

- Production of components for single and multi-cylinder engines

- Creation of functional prototypes and functional samples

- Development and construction of jigs and test equipment

- Modification of existing series parts

- Creation of test specimens for material samples

- Production of small series

OUR PORTFOLIO

Test bench pallets for passenger car, commercial vehicle and large engines

- Special motor pallets are used to enable a high degree of flexibility during tests on the test bench

- the motor is mounted on a pallet away from the test bench

- This shortens set-up times and thus increases the efficiency of data determination

- In addition to car engine pallets, WTZ Roßlau also offers engine pallets for commercial vehicles and large engines

MANUFACTURING PROCESS

MILLING AND DRILLING

CNC machining up to a dimension of 2000 x 1600 x 1500 mm and max. 6 t gross weight

CYCLE CONTROLLED TURNING

Machining up to a dimension of diameter 800 x 3000 mm

CNC manufacturing

Drilling and milling up to a workpiece dimension of 800 x 360 mm.

WELDING AND SOLDERING

Machining of structural steel, stainless steel and aluminum components using TIG, MAG and E welding methods.

OTHER

External cylindrical grinding, surface grinding, sawing, assembly work

INDUSTRY SOLUTIONS

- Engine components

- Complex components

- Pipelines

- Engine cooling

- Welded assemblies

- Exhaust pipe

- Cooling water systems

- Exhaust gas heat exchanger

- Conversion and adaptation of machinery and equipment

- Housing

- Tribometer

- Individual production of engine components

- Welded assemblies and piping

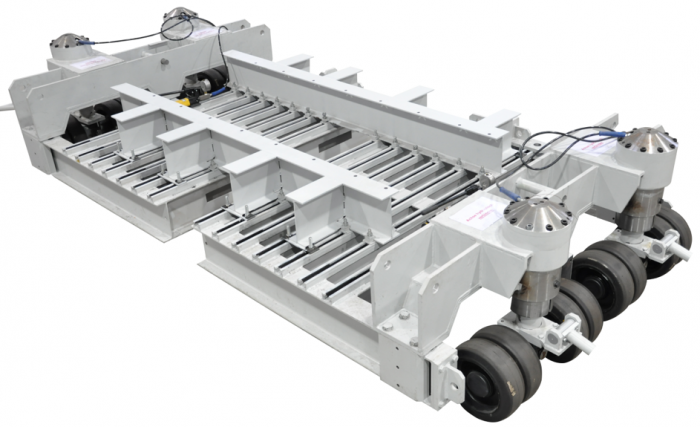

PASSENGER CAR/NFZ PALLET

- the pallets consist of a base frame with rail system

- the base frame is a welded construction consisting of two outer pillars running in the longitudinal direction, which are connected to each other by transverse joints

- There are two T-slotted rails on each of the two outer pillars

- Passenger car and commercial vehicle pallets only differ in terms of dimensions

- Dimensions of the car pallet (length x width x height): 1200mm | 800mm | 250mm

- Dimensions of the commercial vehicle pallet (length x width x height): 1200mm | 1500mm | 250mm

pallet for large engines

- Base frame consisting of two longitudinal connections and four cross connections

- Two steel bridges on two removable heavy-duty axles, each with four wheels

- Axles are fi xed via 12 bolts and can be dismantled

- Rail system with two steel beams for fastening

- Adjustable in both horizontal and vertical directions

- Vertically adjustable : 135 mm

- Mounting surface: 3300 mm x 1930 mm or 4285 mm x 1930 mm

- Dimensions (length x width x height): 3300 – 4285 mm | 1930 mm | 348 – 478 mm