Development of a PEM high-pressure electrolysis stack with process heat extraction, a high-pressure H2 compressor and an emission-free cycle engine at the WIR! starting point Sonneberg - PEM4Heat

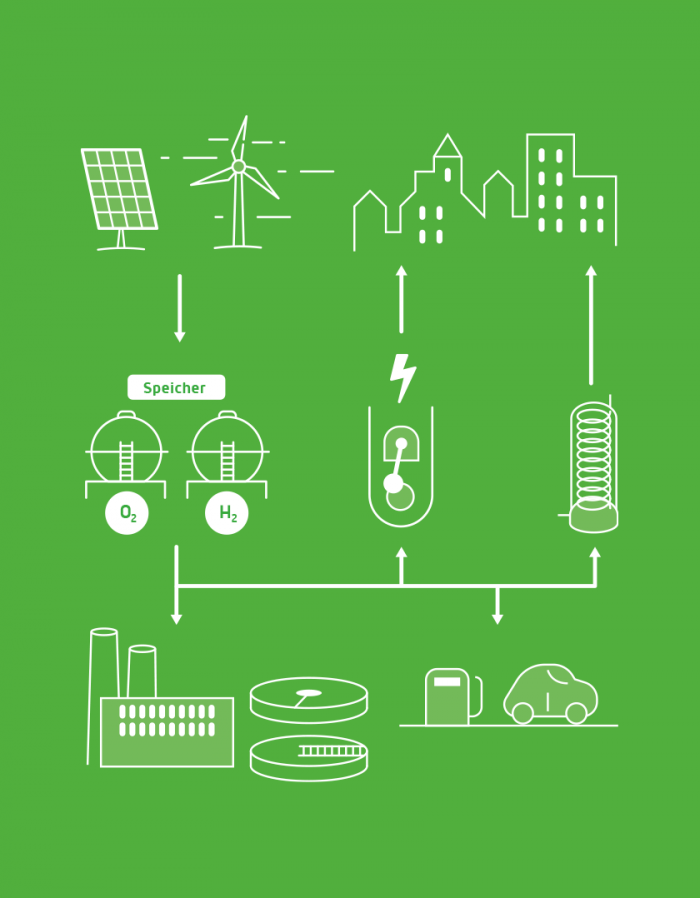

The joint project PEM4Heat at the Sonneberg base location includes the further development of a combined heat and power plant with a hydrogen-oxygen cycle engine as well as a novel and innovative H2 high-pressure compressor (up to 1000 bar) and its process heat extraction (PEM electrolyzer, CHP) to demonstrate the safe and sustainable (CO2-neutral) heat supply of neighborhoods and H2 processing for the mobility sector.

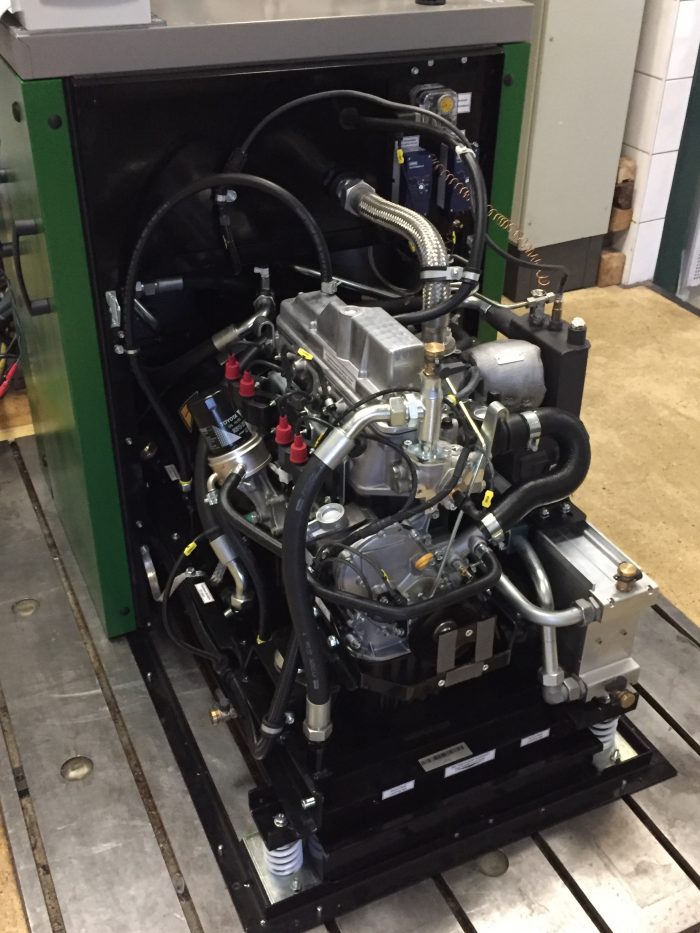

The sub-project of WTZ Roßlau gGmbH has the overall objective of developing a 20 kW CHP plant in which an efficiency-optimized and continuously running hydrogen-oxygen cycle engine is integrated. This innovative engine concept has zero exhaust emissions and enables unprecedented efficiency.

The goal is to be achieved through the further development of the zero-emission cycle process. In this process, the gases oxygen and hydrogen produced during pressure electrolysis are converted into water in a combustion engine with zero emissions. The zero-emission cycle engine has the potential to become an integral key technology for a high-performance energy storage system, together with pressurized electrolysis and gas storage.

At the end of the project, there will be a demonstration of all components at Sonneberg town hall in early 2024. The zero-emission CHP unit developed by the WTZ will also be put into operation in front of the public. The implementation is recorded on the town hall website:

https://sonneberg.de/rathaus/gefoerderte-massnahmen/forschungsvorhaben-wasserstoff/baufortschritt.html