Common rail-fuel-water emulsion

Project description

A fuel system that was suitable for providing a fuel-water emulsion in common rail systems and two solutions for injectors which can inject a fuel-water emulsion in diesel engines using the common rail method were developed during this project.

A simple and low-maintenance Venturi mixer is used as the mixing device, with which a propulsive jet of fuel is used to create the emulsion together with the water, which is also under pressure. The design took place using 1D and 3D tools. Tests on the injection test stand and on the engine confirmed the outstanding quality of the emulsion that was created.

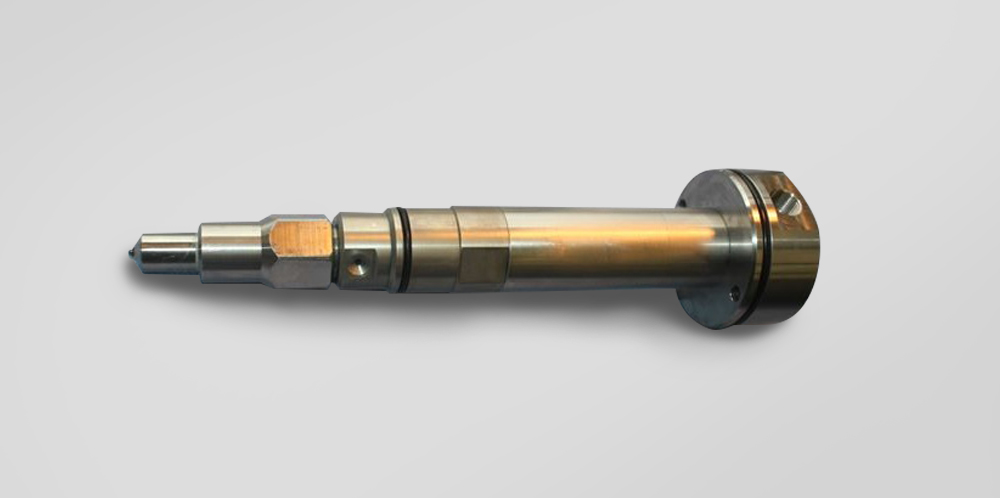

Furthermore, as part of the project a common rail injector was also geometrically and materially modified in the pilot valve, which is extremely susceptible to cavitation wear. This made it possible to increase its run time several times over without failure using an externally mixed fuel-water emulsion. Water rates of up to 60 % were used with this injector during the engine tests, and the tremendous potential for reducing nitrous oxide and particle emissions was verified.

The knowledge that was gained led to the development of another injector in which the emulsion is generated inside the injector and the pilot valve is supplied with pure diesel fuel. The principle promises to have the most potential in operation with fuel-water emulsion and will also be advantageous in transient engine operation. Prototype proved its basic functional capability on the injector test stand.