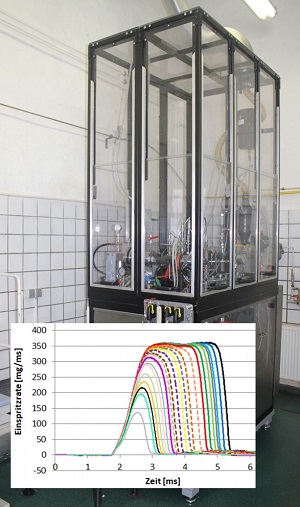

High pressure gas-diesel dual fuel injector experimental set-up

Project description

The increased use of natural gas in engines can lead to significant reductions in climate-damaging carbon dioxide emissions, not just in the automotive sector but also in the areas in which medium-speed large engines are used, and also reduce other engine pollutant emissions. The disadvantages of pre-mixed gas combustion methods (e.g. with regard to efficiency) can be avoided by using a high-pressure gas direct injection strategy. The goal of this research project was to develop high-quality testing facilities for the systematic, experimental investigation of injection behaviour of high-pressure gas injectors.

Test set-ups were developed for two measuring principles, a procedure for measuring the pressure increase and a procedure for measuring the force of the injection jet, and fundamental and (in some cases) promising knowledge was gained. A third measuring device, a prototype of an pneumatic injection analyser, was also adapted to the requirements of large engine gas injectors and successfully operated. On this basis, a testing facility for developing new high-pressure gas diesel dual fuel injectors was set up and optimised. Measurements have shown that the injection rates can be measured with high precision. The test results on the basis of variations such as pressure, injection time and temperature say a great deal about injector behaviour under the different conditions. The test set-up also revealed the suitability thereof for continuous operation.